FINE WIRE WELDING MACHINE

APPLICATION:

floor heating mesh,3D panel covered flat mesh,seedbed mesh, building roof pouring reinforced mesh, Cage mesh

Main Features:

1. Both the line wire and cross wire feeding are from coil wires automatically.

2. Both the line wire spacing and cross wire spacing can be adjusted manually within certain range.

3. The finished product can be in mesh sheet or mesh roll. If the output form is in mesh roll, the machine will be equipped with the mesh coiling machine. If the output form in mesh sheet, th emachine can be equipped with the automatic mesh cutter or manual mesh cutter. The automatic mesh cutter can cut the mesh to the desired length automatically without stop welding.

4. The cross wire can be straightened and cut automatically by the machine itself. And it is equipped special device to cut and feed the cross wire precisely. Therefore, it can save the time and labor cost to slice the burr on the mesh edges. Precise cross wire cutting device patent No.: ZL02208722.2 Precise cross wire positioning device patent No.: ZL02208721.4

5. Mesh pulling system adopts the springy drag link and positioning device ,which make the cross wire spacing size is more accurate, compared with other similar mesh roll welding machines. Springy drag link type mesh pulling device patent No.: ZL200520024380.9

6. The welding device takes new type of transformer with high efficiency. It has 8 different adjustable voltage grades, which enlarge the welding adjusting range and the weldable wire size range.

7. In order to adapt to the power transformer capacity and reduce the current impact, the welding control adopts the way of welding in one time but electricity input in several separate phases, that is (i.e.), the welding transformers work separately when welding one cross wire.

8. The welding adopts electric and electronic synchronous control technique. Both the welding time and separate phase-welding is composed of digital integrated circuit with high speed, stable function, high precision, firm welding spot without welding track. It is easy to operate.

9. In order to make the quota regulation and control more convenient, it takes digital mesh length counting device, electronic counter, and can control the cutting of the mesh cutter. It is very convenient and accurate to regulate the mesh length data.

10. the main structure is more well-set with complete function and compact which take up very small layout space.

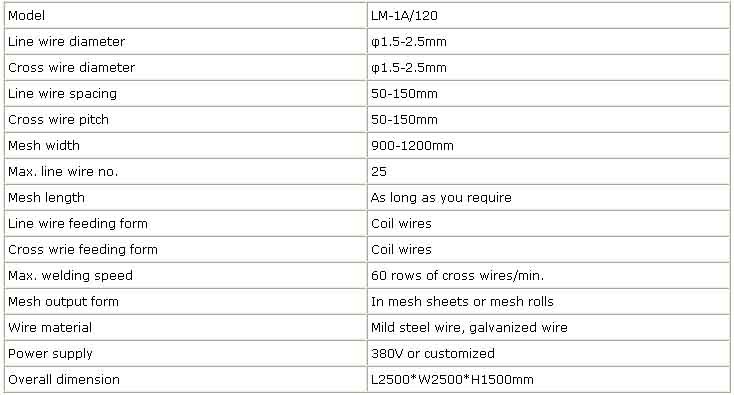

FINE WIRE MESH WELDING MACHINES